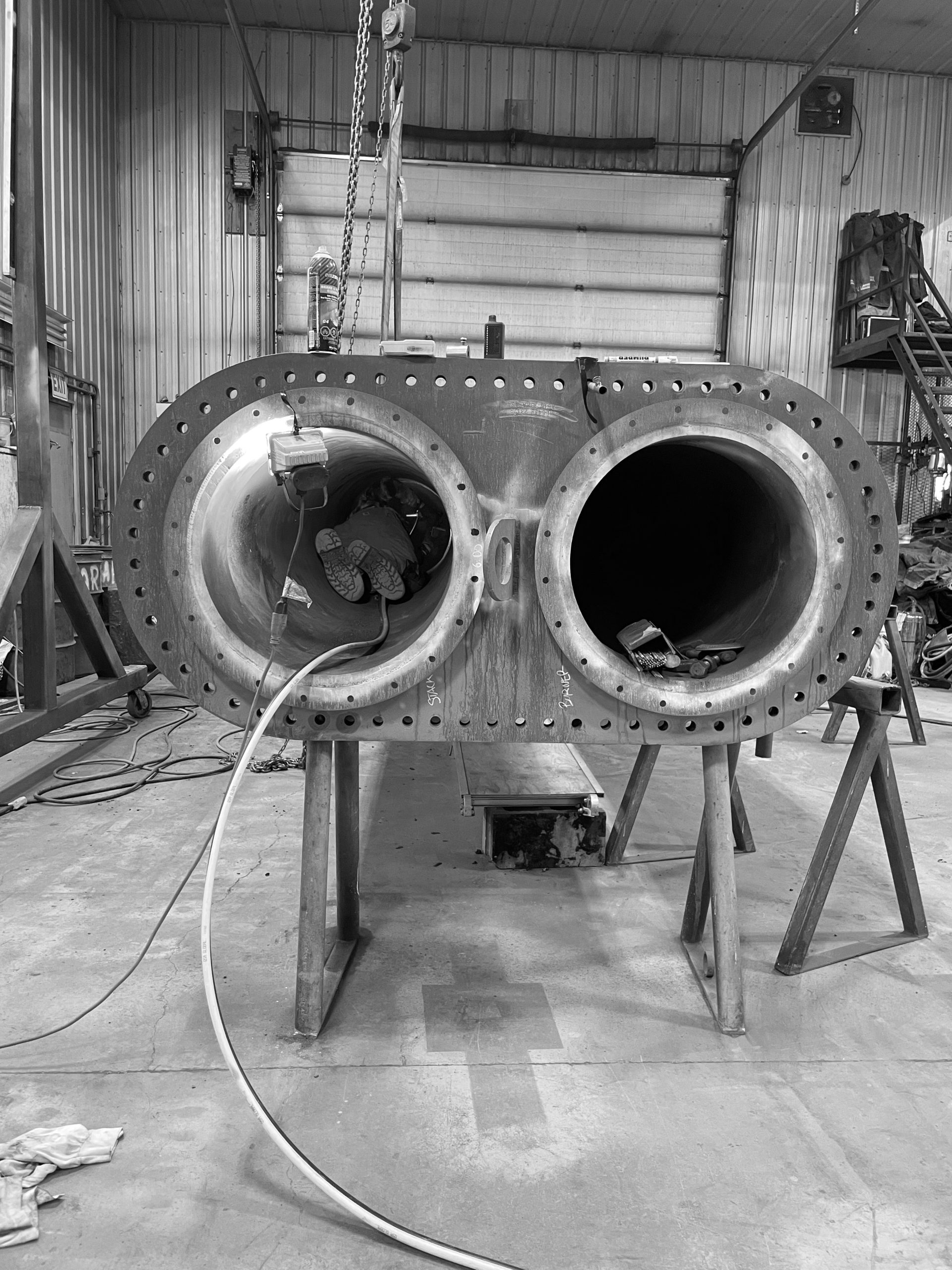

MAGNETIC PARTICLE TESTING

MT or MPI is a non-destructive testing process where a ferromagnetic material is magnetized, and a magnetic flux is induced to determine the existence and extent of macro defects such as cracks. Discontinuities in the material will allow the magnetic field to pass through and once magnetic particles are applied they will mitigate to the flaw and provide clear flaw indication. Examples of ferromagnetic materials include iron, nickel, cobalt and some of their alloys.

Being viewed primarily as a surface examination method, MPI is a very effective method for location of surface breaking and slight sub surface defects, such as cracking, pores, cold lap and lack of sidewall infusion in welds. Magnetic Particle Inspection (MPI) provides very good defect resolution and is used extensively on welded fabrications in magnetic material, castings, locating fatigue cracks in items subject to cyclical stress.

This quick and relatively easy to apply technique is used in a wide range of industries including but not limited to petrochemical, structural steel, power generation and oil & gas.

ADVANTAGES OF MT –

- Portability

- Ease of inspection

- Ability to inspect irregular shapes

- Cost being relatively lower

- Immediate indications of defects

- Shows surface and near surface defects